Lawn Tractor Battery Cables: Essential Maintenance for Sustainable Landscaping

Maintaining your electric lawn tractor's battery cables is crucial for both its longevity and your commitment to sustainable landscaping practices. Neglecting these often-overlooked components can lead to reduced efficiency, premature equipment failure, and ultimately, a larger environmental footprint. This guide provides a step-by-step approach to inspecting, cleaning, and, if necessary, replacing your battery cables, ensuring your electric lawn tractor remains a powerful and environmentally friendly tool. Did you know that a properly maintained battery system can extend the life of your electric mower by up to 25%? For more detailed information on lawn tractor batteries, check out this helpful resource: Lawn Tractor Batteries.

Identifying Cable Issues: Early Detection Prevents Major Problems

Before you begin any repairs, carefully inspect your battery cables for signs of damage or wear. Early identification is key to preventing larger, more costly problems. Here's what to look for:

Corrosion: A whitish, powdery substance on terminals indicates corrosion, hindering electrical conductivity. (Think of it like rust for your electrical system).

Loose Connections: Wobbly or loose connections signal poor power transfer, potentially leading to intermittent operation or damage.

Damaged Insulation: Cracks, fraying, or melted areas in the cable insulation expose wires, creating a significant fire hazard and short-circuit risk.

Broken Wires: Visible breaks or internal wire damage prevent proper current flow.

Tools and Materials: Gathering Your Equipment

To effectively maintain your battery cables, gather the following tools and materials:

- Wire brush (brass recommended): For gently removing corrosion.

- Wrench (correct size for terminals): To securely tighten connections. Using the incorrect size can cause damage.

- Terminal cleaner: A specialized cleaner to efficiently remove stubborn corrosion.

- Dielectric grease: A protective lubricant preventing future corrosion and ensuring a reliable connection.

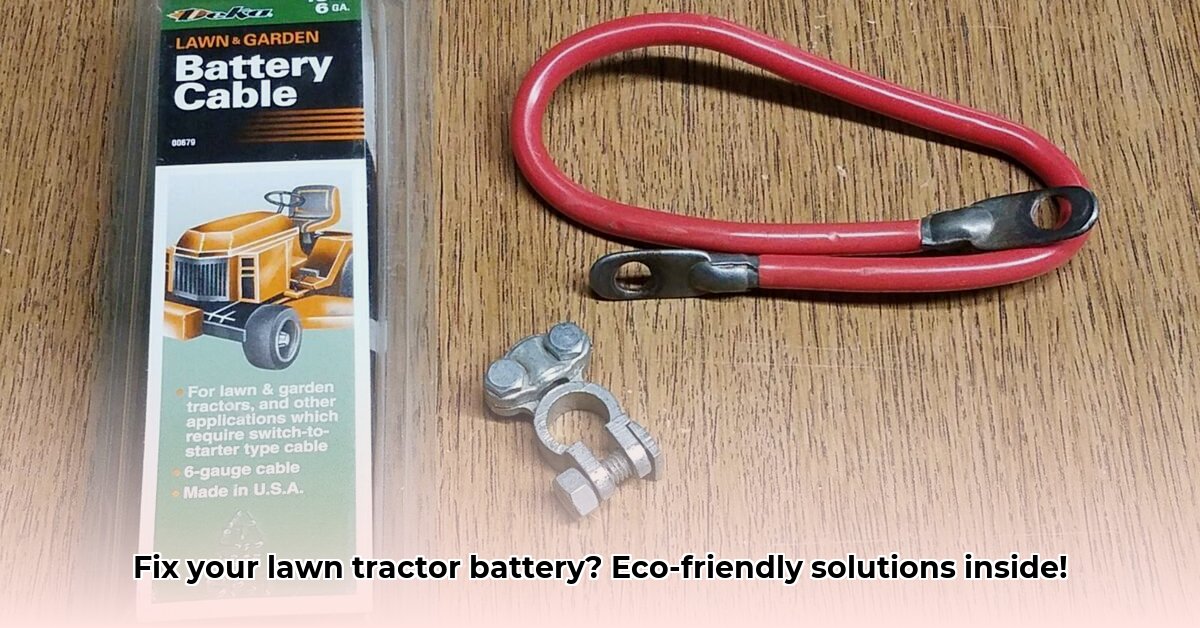

- Replacement cables (if needed): Ensure you purchase cables of the correct gauge (thickness) for your tractor model. Check your owner's manual for specifications.

- Cable ties: To neatly secure connections and prevent stray wires.

- Safety glasses: Essential for eye protection during the process.

Step-by-Step Cleaning and Maintenance: A Practical Approach

Follow these steps carefully to clean and maintain your battery cables:

Safety First: Disconnect the Battery: Always disconnect the negative (-) terminal first to prevent accidental shorts.

Clean the Terminals: Use the wire brush and terminal cleaner to thoroughly remove corrosion from both battery terminals and cable ends.

Inspect the Cables: Carefully examine the entire length of each cable for damage to the insulation or wires.

Apply Dielectric Grease: Apply a thin layer of dielectric grease to the cleaned terminals before reconnecting.

Reconnect the Battery: Attach the positive (+) terminal first, then the negative (-), ensuring secure but not overly tight connections. Use cable ties to neatly secure any loose cables.

Troubleshooting Common Problems: Quick Solutions to Frequent Issues

Encountering problems? This table provides quick solutions to common battery cable issues:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Slow cranking | Corrosion, loose connections, weak battery | Clean terminals, check connections, test battery voltage |

| No cranking | Broken cables, dead battery | Inspect cables, test battery, consider battery replacement |

| Intermittent power | Loose connections, damaged insulation | Tighten connections, replace damaged cables |

| Sparks at connections | Corrosion, loose connections | Clean terminals, apply dielectric grease, tighten connections |

Cable Replacement: A Comprehensive Guide

If your cables are beyond repair (severe insulation damage, broken wires), replacement is necessary. When selecting replacement cables, always ensure they have the correct gauge (thickness) specified in your tractor's manual. Follow the cleaning and connection steps outlined above for proper installation.

Preventive Maintenance: Extending Cable Lifespan

Regular maintenance significantly extends the life of your battery cables:

Monthly Inspections: Visually inspect cables at least monthly for any signs of wear or damage.

Semi-Annual Cleaning: Clean terminals and connections every six months, or more frequently in humid climates.

Proper Storage: Store your tractor in a dry place when not in use to minimize corrosion.

Conclusion: Sustainable Landscaping Through Proactive Maintenance

Proactive battery cable maintenance is integral to sustainable landscaping. By following these steps, you extend the life of your equipment, reduce environmental impact through longer equipment usage, and save money on repairs. Remember, taking care of the details makes a real difference in both performance and environmental responsibility. Is it worth the extra effort to maintain your lawn tractor's battery cables for a healthier planet? Absolutely.